Mobile car depollution

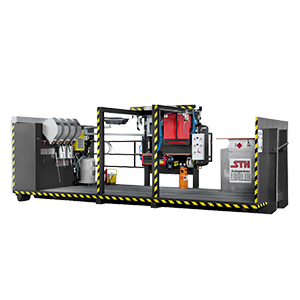

The mobile vehicle drainage station was developed to provide comprehensive mobility. The H10 / H12 also offer a complete workstation to guarantee a productive and safe workflow.

Our vehicle drainage station stands for comprehensive mobility

With our two variants, we can map all environmental conditions to meet your requirements and thus offer the optimum solution for draining.

Set up - Connect the power supply - Be ready for operation

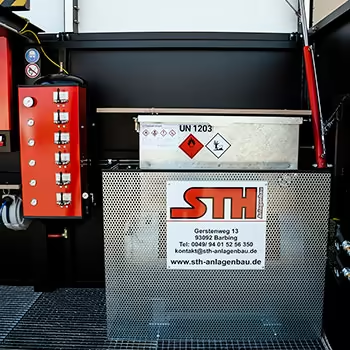

The drainage technology is the same for all station types on offer and is of course also supplied by STH Anlagenbau GmbH. The media containers meet the legal requirements for water-polluting liquids in the corresponding hazard classes and are equipped with overfill protection, limit value sensors and venting units.

Pumps, hose reels, level indicators, tank tapping devices and all tools are products that have proven themselves in demanding practical use, that have already undergone multiple technical optimization and that all comply with the relevant directives.

The equipment carrier consists of a tubular frame construction with a floor pan, which is dimensioned in accordance with the Water Management Act and covered with gratings.

Note

The petrol or diesel fuel obtained is filtered and processed for refueling the company's own vehicles (using an automatic nozzle).

Throughput

The draining time of a vehicle was determined using the compressed air-based process offered with set-up times of approx. 15 minutes. When used optimally, the system can dry around 32 vehicles within one working day, assuming a working time of 8 hours.

Technical Data

Equipment

- Support frame with 3 tons load

- Drip tray under work area

- Fuel tanks are equipped with overfill protection and venting device

- Fuel cylinders and filters for cleaning gasoline and diesel for internal reuse

- Tank system with automatic nozzles for gasoline and diesel fuel

- Compressed air build-up is regulated by means of a compressed air tank (90 l)

- Petrol/diesel drilling unit STH/TBR/-01 for extracting liquid/gaseous substances

-

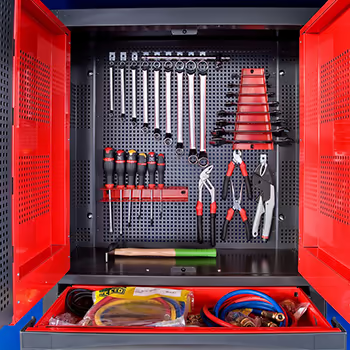

Complete tool kit for dismantling vehicles, including

- Probe set

- Pneumatic tool

- Spiral hoses

- hand tool

- Facom waste oil kit

Characteristics

- Complete solution

- System ready for operation

- Quick system installation

- Reliable operation

- Field-tested system concept

- Development and production according to current guidelines

- High level of occupational safety thanks to cleanliness in the workplace

- Highest quality standards

EXCLUSIVELY AT STH-003 E/12/H

- Integrated roof

- Lockable workspace

Electronics

- Overfill protection for all fluids

- Optical and acoustic warning signal

- petrol consisting of LS300, LS500, QB200

- diesel consisting of 76A and NB220

- Maximelder (coolant, windshield washer fluid, used oil)

Tank storage

- Rietberg KC 500 liters

- Rietberg GS 270 liters

- Brake fluid container 75 liters